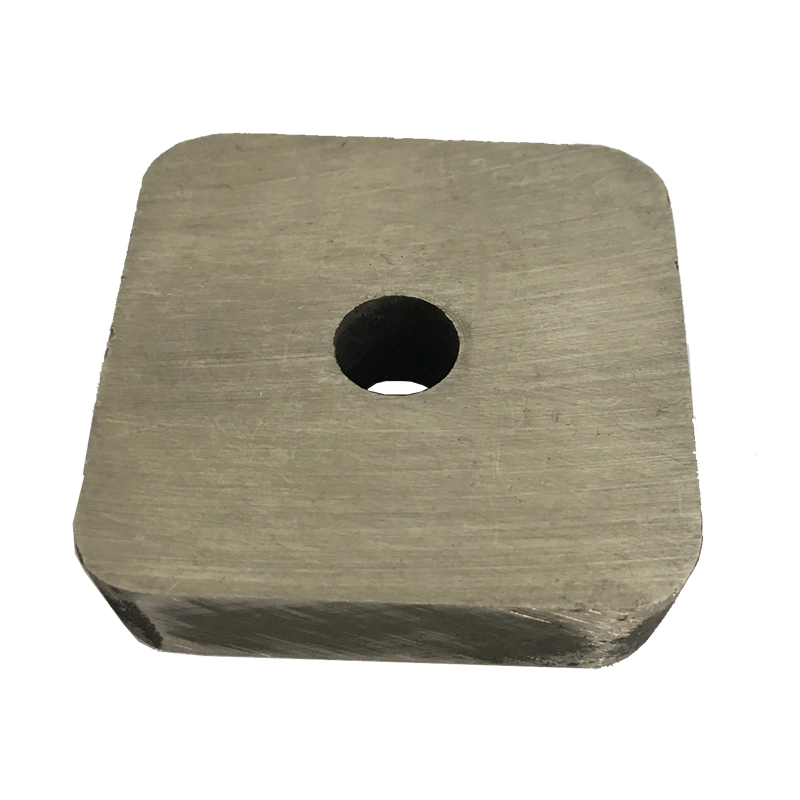

Safety Hot Selling Block AlNiCo Magnet

AlNiCo magnet, including cast AlNiCo and sintered AlNiCo, have the vast rang of complex shapes and sizes at economical c

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | SDMNB |

| Certification | ISO9001:2008, ISO/Ts16949:2009, RoHS |

| Size | Customized |

| Other Coating | Ni, Ni-Cu-Ni, Zn(Cr3+), Tin, Epoxy, Ni-AG, Ni-Au |

| Tolerance | +/-0.05 |

| Delivery Detail | 10~20 Days After Order Confirmed |

| Export Markets | Global |

| OEM Service | Yes |

| Transport Package | Sea Pallet / Air Carton / Express Packaging |

| Specification | RoHS |

| Trademark | SDM |

| Origin | China (Mainland) |

| HS Code | 8505111000 |

| Production Capacity | 100, 000 PCS/Month |

Product Description

AlNiCo magnet, including cast AlNiCo and sintered AlNiCo, have the vast rang of complex shapes and sizes at economical cost. They are slao ideal for high temperature applications up to 500 º C.

1. Features:

Vast range of complex shapes and sizes;

Economical cost;

Ideal for high temperature application up to 550 ° C.

2. Applications: Automobile parts, sensors, magnetic chucks, guitar pickup, audio apparatus, electronic motors, educational equipment and aerospace equipments, etc.

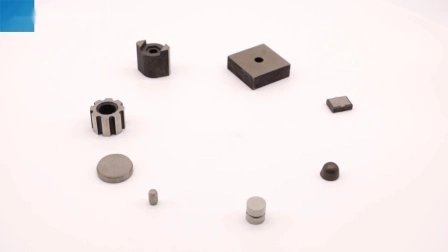

3. Shape: Disc, Ring, Block, Segment, Cylinder, U shape, Customized Design.

4. Size: Customized size per your requirements.

5. Certification: ISO9001: 2008, ISO/TS16949: 2009 and RoHS.

Our advantages

A: Over 10 years in manufacturing magnets and over 4 years as a gold supplier on Alibaba

B: As a supplier of Siemens Ltd Australia, GM, BMW, BENTLEY, and REGAL BELOIT in European, we are very experienced in control quality, solve problems and select magnet materials.

C: The price will be more competive as we have our own factory.

D: We have many grade materials in our stock to help you to let the lead time shorter.

About us:

Hangzhou SDM Magnetics is one of the professional manufacturers of permanent magnets in China. With an experienced team, SDM is specialized in producing various kinds of permanent magnets, including Sintered & Bonded NdFeB, Cast & Sintered AlNiCo, Sintered SmCo Magnets and relevant Magnetic Assemblies such as pump couplings and holding devices.

In order to satisfy our customer's needs, SDM focuses on quality control with continuous improvements on all manufacturing processes and provides the most competitive prices based on domestic resources. Customized magnets are always available here.

After effective marketing, our products are provided to customers such as GM, BMW, BENTLEY, Siemens and REGAL BELOIT in European, North and South America and Asia-Pacific markets. Our magnets are widely used in magnetic motors, automotive instruments, medical equipments, wind-power generation, aerospace and military industries.

We are located in Hangzhou, near to the Shanghai air port and harbor. Traffic is convenient. We wish new and old friends from all walks of life to contact us for future business relationships and mutual success!

FAQ

1: How long will you give me the reply?

We will contact you in 12 hours as soon as we can.

2: Could I get samples?

Yes, we have materials in stock to help you to get the samples as soon as we can.

3: How about the quality of the magnets?

We have the certification of ISO, TS and ROSH, we could send the certification test of our company to you.

4: How is the price?

As we believe the quality is the most important, we will provide the best quality magnet we can with reasonable price.

5: Could you provide me the shortest lead time?

We have materials in our stock, if you really need, you can tell us and we will try our best to satisfy you.

6: Could I visit your factory?

Of course, if you need we will help you to visit our factory.

7: If I have paid, when will you help me to produce?

When we have received the money in our account, we will give you the receipt and arrange to produce immediately.

| / Cast AlNiCo Magnet | |||||||||||

| Grade | MMPA Equivalent | ||||||||||

| Residual Induction (Br) | Coercive Force (Hcb) | Max Energy Product (BH)max | Temp. Coefficient Tk | Curie Temp. | Max Working Temp. | ||||||

| mT | Gs | kA/m | Oe | kJ/m³ | MGOe | %/ºC(Br) | %/ºC(Hcj) | ºC | ºC | ||

| LN10 | 600 | 6000 | 40 | 500 | 10 | 1.2 | -0.02 | -0.03 | 810 | 450 | ALNICO 3 |

| LNG12 | 700 | 7000 | 44 | 550 | 12 | 1.5 | -0.02 | -0.03 | 810 | 450 | ALNICO 2 |

| LNG13 | 680 | 6800 | 48 | 600 | 13 | 1.63 | -0.02 | -0.03 | 810 | 450 | ALNICO 2 |

| LNG18 | 900 | 9000 | 48 | 600 | 18 | 2.25 | -0.02 | -0.03 | 850 | 450 | ALNICO 4 |

| LNG37 | 1200 | 12000 | 48 | 600 | 37 | 4.63 | -0.02 | -0.03 | 860 | 525 | ALNICO 5 |

| LNG40 | 1250 | 12500 | 48 | 600 | 40 | 5 | -0.02 | -0.03 | 860 | 525 | |

| LNG44 | 1250 | 12500 | 52 | 650 | 44 | 5.5 | -0.02 | -0.03 | 860 | 525 | |

| LNG52 | 1300 | 13000 | 56 | 700 | 52 | 6.5 | -0.02 | -0.03 | 860 | 525 | ALNICO 5DG |

| LNG60 | 1330 | 13300 | 60 | 750 | 60 | 7.5 | -0.02 | -0.03 | 860 | 525 | ALNICO 5-7 |

| LNGT18 | 580 | 5800 | 90 | 1130 | 18 | 2.25 | -0.02 | -0.03 | 860 | 550 | |

| LNGT28 | 1000 | 10000 | 58 | 720 | 28 | 3.5 | -0.02 | -0.03 | 860 | 525 | ALNICO 6 |

| LNGT32 | 800 | 8000 | 100 | 1250 | 32 | 4 | -0.02 | -0.03 | 860 | 550 | ALNICO 8 |

| LNGT38 | 800 | 8000 | 110 | 1380 | 38 | 4.75 | -0.02 | -0.03 | 860 | 550 | |

| LNGT44 | 850 | 8500 | 120 | 1500 | 44 | 5.5 | -0.02 | -0.03 | 860 | 550 | |

| LNGT48 | 900 | 9000 | 120 | 1500 | 48 | 6 | -0.02 | -0.03 | 860 | 550 | |

| LNGT60 | 950 | 9500 | 110 | 1380 | 60 | 7.5 | -0.02 | -0.03 | 860 | 550 | |

| LNGT72 | 1050 | 10500 | 112 | 1400 | 72 | 9 | -0.02 | -0.03 | 860 | 550 | ALNICO 9 |

| LNGT88 | 1100 | 11000 | 115 | 1450 | 88 | 11 | -0.02 | -0.03 | 860 | 550 | |

| LNGT36J | 700 | 7000 | 140 | 1750 | 36 | 4.5 | -0.02 | -0.03 | 860 | 550 | ALNICO 8HC |

| *. | |||||||||||

| *The above-mentioned data of magnetic properties and physical properties are given at room temperature. | |||||||||||

| *\. | |||||||||||

| *The max working temperature of magnet is changeable due to length-diameter ratio, coating thickness and another environment | |||||||||||

| / Sintered AlNiCo Magnet | |||||||||||

| Grade | MMPA Equivalent | ||||||||||

| Residual Induction (Br) | Coercive Force (Hcb) | Max Energy Product (BH)max | Temp. Coefficient Tk | Curie Temp. | Max Working Temp. | ||||||

| mT | Gs | kA/m | Oe | kJ/m³ | MGOe | %/ºC(Br) | %/ºC(Hcj) | ºC | ºC | ||

| FLN8 | 500 | 5000 | 40 | 500 | 9 | 1.13 | -0.02 | -0.03 | 760 | 450 | ALNICO 3 |

| FLNG12 | 700 | 7000 | 48 | 600 | 12.4 | 1.55 | -0.02 | -0.03 | 810 | 450 | ALNICO 2 |

| FLNGT18 | 600 | 6000 | 90 | 1130 | 18 | 2.2 | -0.02 | -0.03 | 860 | 450 | |

| FLNG34 | 1200 | 12000 | 48 | 600 | 34 | 4.25 | -0.02 | -0.03 | 890 | 450 | ALNICO 5 |

| FLNG37 | 1250 | 12500 | 48 | 600 | 37 | 4.63 | -0.02 | -0.03 | 890 | 450 | |

| FLNGT28 | 1050 | 10500 | 60 | 600 | 28 | 3.5 | -0.02 | -0.03 | 850 | 450 | ALNICO 6 |

| FLNGT38 | 800 | 8000 | 120 | 1500 | 38 | 4.75 | -0.02 | -0.03 | 850 | 450 | ALNICO 8 |

| FLNGT42 | 880 | 8800 | 120 | 1500 | 42 | 5.25 | -0.02 | -0.03 | 820 | 450 | |

| FLNGT36J | 700 | 7000 | 140 | 1750 | 33 | 4.13 | -0.02 | -0.03 | 850 | 450 | ALNICO 8HC |

| *. | |||||||||||

| *The above-mentioned data of magnetic properties and physical properties are given at room temperature. | |||||||||||

| *\. | |||||||||||

| *The max working temperature of magnet is changeable due to length-diameter ratio, coating thickness and another environment factors. | |||||||||||

Related Products

-

![Heavy Duty 1 Ton Permanent Magnetic Chuck/Magnetic Lifting]()

Heavy Duty 1 Ton Permanent Magnetic Chuck/Magnetic Lifting

-

![Permanent Magnetic Chuck for Lathe Drill Milling CNC Machine Magnetic Holder Table]()

Permanent Magnetic Chuck for Lathe Drill Milling CNC Machine Magnetic Holder Table

-

![Rubber Magnetic Flexible 3D Refrigerator Epoxy Resin Souvenir Gift Fridge Sticker Magnet]()

Rubber Magnetic Flexible 3D Refrigerator Epoxy Resin Souvenir Gift Fridge Sticker Magnet

-

![Sine Plate Permanent Magnetic Chuck Lathe Part Tool Holdercollet Chuck]()

Sine Plate Permanent Magnetic Chuck Lathe Part Tool Holdercollet Chuck